As with any product, most manufacturers claim to have some kind of secret ingredient that makes their vinyl plank more durable than the competitors. And since there is such a massive range of products on the market, figuring out which product is the actual best can be quite a chore. The good news is there are a few key elements that will determine the longevity of your flooring and we are here to share those secrets.

Understanding the Main Layers of Vinyl Plank

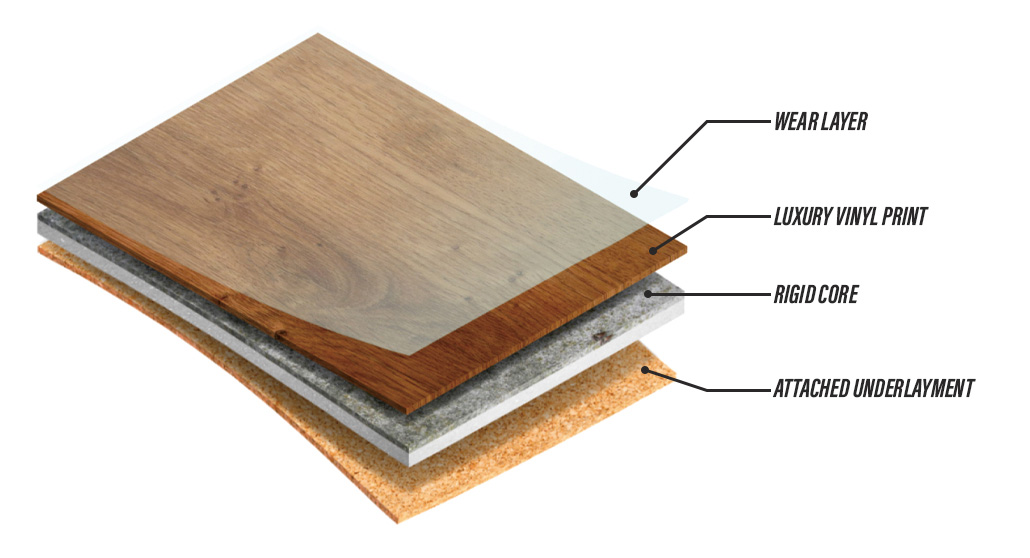

Vinyl planks range in width from 6- to 12-inches. Luxury Vinyl is usually composed of four layers, which each contribute to its superior durability. The backing layer protects both the subfloor and the plank and the core layer provides stability. Next comes the design layer which is a realistic 3D printed image that gives LVP the ability to mimic real hardwood so beautifully. A transparent wear layer covers and protects the design layer from dents, scratches and damage.

The Importance of Wear Layers

Some companies only use one vinyl or urethane layer above the print layer while others use two distinct wear layers. Either way, these layers are by far the most important element contributing to the durability of your vinyl plank floor.

The three most common terms you’ll come across when researching surface layers are: Vinyl No wax, Urethane, and Enhanced Urethane. What do they mean? Which is best? So many questions arise, but don’t worry. We are here to simplify these terms and help you determine the best product for your lifestyle.

Vinyl No Wax is a clear top coat of vinyl. Though it is tough, it is not the best in terms of maintaining the appearance of your floor as it is much more prone to dulling than other materials.

Urethane is a step in the right direction, but in terms of protection, it’s nothing special on its own.

Some companies ‘enhance’ their urethane with aluminum oxide and microscopic ceramic or silica beads. There are many variations in this and it ultimately comes down to the individual company. Higher quality floors come with an enhanced urethane surface layer.

Thickness of The Wear Layer

Other than the quality and composition of the wear layer, another important component is the thickness of your wear layer. In fact, this might be the most important element and the one that allows you to easily differentiate between the vast selection of products on the market.

In general, the thicker the better. Keep in mind, we are not talking about the overall thickness of the planks. What we are looking at is the thickness of the actual wear layer itself.

The terminology used to measure thickness is sometimes confusing so let’s clarify: when a product is marked as 40mil thick, this does not mean 40 millimeters thick. A mil is one thousandth of an inch. To simplify, 1mm equals about 40mil. Wear layer thicknesses typically range from 0.1mm- 1mm (4mil – 40mil) and the thicker the overall wear layer, the better.

As is often the case, higher quality products are reflected in the pricing. A thicker wear layer is generally going to mean a higher price tag. In fact, this is probably the single biggest contributor to the overall cost of your flooring.

If durability is your main concern, a 20mil or higher is going to be your best bet, which is the standard for commercial grade use. That’s not to say a thinner wear layer is totally unacceptable. A thinner wear layer can last just as long in homes without children or pets, and with generally less foot traffic to cause wear and tear. But the more active your home is, the more protection you’re going to want on those floors.

The thickness of your wear layer is almost a direct correlation to the length of the warranty, which further illustrates the importance of a suitable wear layer.

How Does It Compare with Other Options?

One of the biggest reasons vinyl flooring became so popular in its inception was because of its low cost and high durability. Since the 40’s, things have drastically improved. Luxury Vinyl Plank is among the most durable flooring solutions on the market today. In fact, it is more stable and more durable than hardwood and will maintain its look for many more years without any need for re-finishing.

The bottom line is that the durability of vinyl flooring really comes down to understanding the composition and different materials used in each product and the importance of the wear layer thickness. As a general guide, thicker wear layers mean better quality and more durability …and a higher price tag.

By purchasing flooring with a high-quality wear layer, you’ll get a low-maintenance, extremely durable floor that will last for years to come.

Prelude Version 2.1

Prelude Version 2.1